Exploring the Best Rotor Magnet Types for 2026 Trends and Innovations?

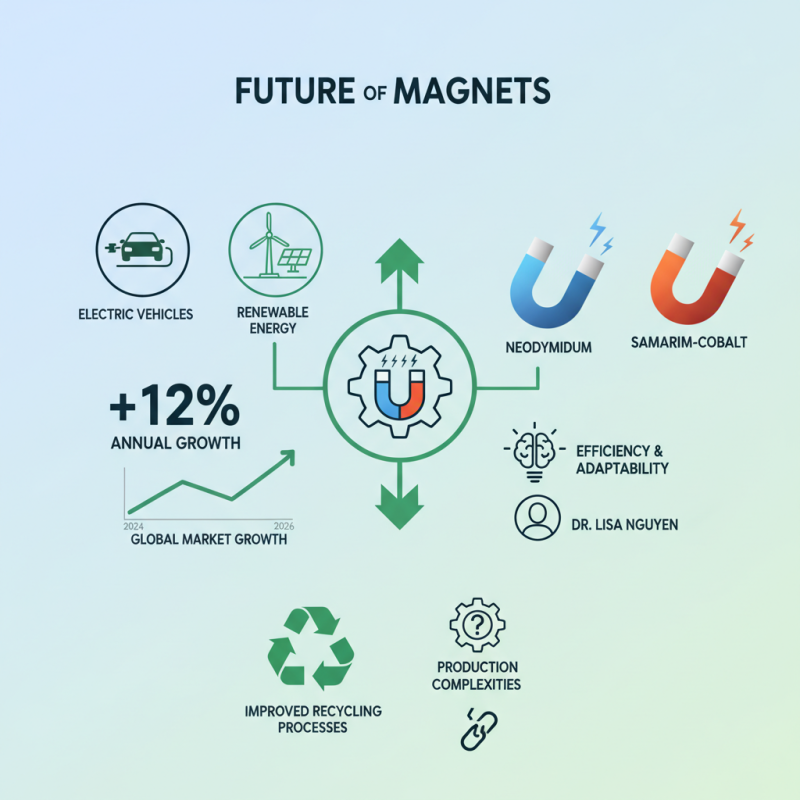

In the rapidly evolving landscape of electromagnetic technology, the "rotor magnet" industry stands at the forefront of innovation. By 2026, trends indicate a shift towards more sustainable and efficient magnet solutions. According to the latest report by the International Electromagnetic Association, the global rotor magnet market is projected to grow by 12% annually, driven by the rising demand in electric vehicles and renewable energy.

Expert Dr. Lisa Nguyen, a leading figure in magnetic technologies, emphasizes the importance of these advancements. She states, "The future of rotor magnets lies in their efficiency and adaptability." This sentiment resonates with manufacturers aiming to optimize performance while reducing environmental impact.

However, challenges remain. The transition to new magnet types, such as neodymium and samarium-cobalt, introduces complexities in production. There is a pressing need for improved recycling processes to handle end-of-life products. As the industry strives to innovate, it is crucial to reflect on these hurdles and strive for smarter solutions in rotor magnet development.

Types of Rotor Magnets: An Overview of Current Options

Rotor magnets play a crucial role in various applications, especially in electric motors and generators. Understanding the types of rotor magnets is essential for embracing innovations in 2026.

Permanent magnets, such as neodymium and ferrite, offer different benefits. Neodymium magnets are known for their high magnetic strength. They are compact and lightweight, which is valuable for many designs.

Ferrite magnets are another popular option. They are more affordable and resistant to demagnetization. However, they generally offer lower performance than neodymium variants. In recent developments, there’s a growing interest in hybrid magnets. They combine the benefits of both neodymium and ferrite. These hybrids can optimize performance while managing costs.

It's important to reflect on the limitations of existing technologies. Every type of rotor magnet has pros and cons. Neodymium magnets may provide high performance, but they are costlier and scarce. Meanwhile, ferrite magnets, while economical, might not meet advanced requirements in some applications. Thus, selecting the right type is often a balancing act. This careful consideration will shape innovations in the upcoming years.

Emerging Trends in Rotor Magnet Technology for 2026

The rotor magnet technology landscape is set to evolve significantly by 2026. Recent reports indicate that demand for high-performance rotor magnets will surge, driven by advances in electric vehicles. According to a McKinsey report, the market for such magnets is expected to grow by 20% annually. This rapid growth is partially fueled by the increased focus on renewable energy sources.

In addition to electric vehicles, businesses are also looking at lightweight materials for rotor magnets. New composite materials are being developed that can provide similar, if not superior, magnetic performance while reducing weight. These innovations could potentially enhance the efficiency of various machines, including wind turbines. However, challenges remain in balancing cost and performance. Companies need to weigh the benefits of these advanced materials against the economic feasibility of widespread adoption.

Moreover, sustainability is becoming increasingly important in the rotor magnet sector. With regulations tightening around waste, manufacturers are exploring recycling options for rare earth materials. This shift is necessary, but not fully developed yet. Progress in this area may be slow, raising questions about the impact on supply chains. As the industry pushes forward, understanding these trends will be crucial for stakeholders.

Exploring the Best Rotor Magnet Types for 2026 Trends and Innovations

| Magnet Type | Composition | Magnetic Strength (T) | Temperature Stability (°C) | Cost per kg ($) | Expected 2026 Adoption Rate (%) |

|---|---|---|---|---|---|

| Neodymium (NdFeB) | Neodymium, Iron, Boron | 1.4 - 1.5 | 80 - 230 | 60 - 80 | 45 |

| Samarium-Cobalt (SmCo) | Samarium, Cobalt | 1.2 - 1.4 | 150 - 350 | 80 - 120 | 30 |

| Ferrite | Iron Oxide, Barium or Strontium | 0.3 - 0.5 | -40 - 250 | 5 - 15 | 20 |

| Alnico | Aluminum, Nickel, Cobalt | 0.8 - 1.2 | -200 - 550 | 20 - 40 | 10 |

| Rare Earth | Various Rare Earth Elements | 1.0 - 1.3 | 100 - 300 | 50 - 90 | 25 |

Innovative Materials and Manufacturing Techniques for Rotor Magnets

The evolution of rotor magnets is driven by innovative materials and advanced manufacturing techniques. For instance, the global market for rotor magnets is projected to reach $30 billion by 2026, according to industry forecasts. This growth presents opportunities for materials like rare earth elements. Yet, sourcing these materials sustainably remains a challenge.

New manufacturing techniques like 3D printing and advanced sintering processes are emerging. These methods reduce waste and lower production costs. A recent report highlighted that 3D printing can cut component production time by 70%. However, the quality of printed magnets must improve. Balancing performance with eco-friendly practices is a key concern.

Magnetic performance is crucial. Innovations in composite materials show promise but may lack the magnetic strength of traditional options. Researchers are exploring alternatives like bonded magnets, which could offer a unique balance of strength and weight. Yet, the technology is still in its infancy. Continuous refinement and testing will be necessary to achieve market readiness.

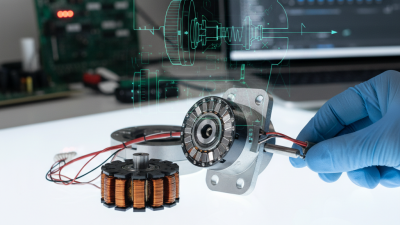

Applications of Rotor Magnets in Various Industries

Rotor magnets play a crucial role across various industries. They are essential in electric motors, wind turbines, and generators. In these applications, the choice of magnet type is vital. Stronger magnets lead to more efficient systems. Yet, not all magnets perform equally under different conditions. This variability can pose challenges during production.

In automotive applications, rotor magnets are used in electric vehicles. These magnets help improve motor efficiency and extend battery life. However, they also face issues related to heat and aging. Finding optimal materials is an ongoing challenge. Similarly, in aerospace, rotor magnets must endure extreme conditions. The quest for lightweight yet durable magnets continues in this sector as well.

Some industries yield better results with different magnet types. The manufacturing sector often experiments with various formulations. This leads to innovative solutions, but it requires significant investment. Industry leaders need to balance performance with cost. These reflections highlight the importance of ongoing research and development in rotor magnet technology.

Applications of Rotor Magnets in Various Industries (2026 Trends)

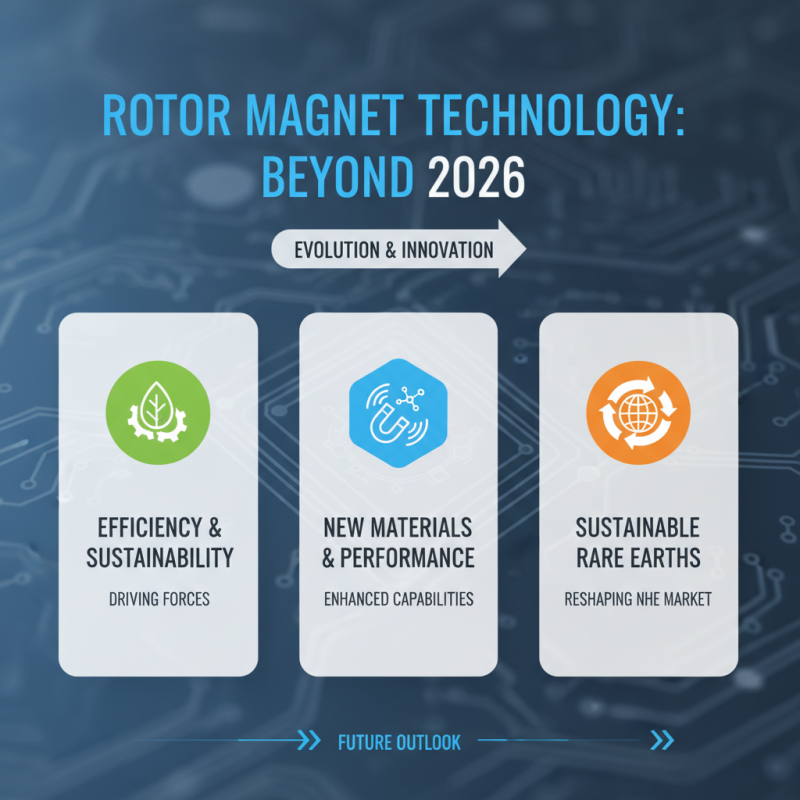

Future Projections: Rotor Magnet Developments Beyond 2026

As we look beyond 2026, rotor magnet technology will evolve significantly. The push for efficiency and sustainability will drive innovation. New materials are being explored. They promise enhanced performance and reduced environmental impact. For instance, efforts are underway to harness rare earth elements more sustainably. This could reshape the market.

In aspects of design, compactness becomes key. Lighter, more powerful magnets will lead to smaller motors. However, challenges remain. Not all materials can meet the stringent efficiency standards. Researchers are still grappling with trade-offs between strength and cost. These imperfections must be addressed for practical applications.

Ultimately, the trajectory of rotor magnets will reflect our broader technological landscape. As we push for advancements, we must also consider the ethical implications. Balancing innovation with environmental responsibility is crucial. The path ahead is not without obstacles, but the potential for breakthroughs is immense.

Related Posts

-

What is Rotor Magnet and How Does it Work in Electric Motors

-

2026 Best Rotor Magnet Models for Your Projects?

-

2025 Top 5 Innovations in Axial Flux Permanent Magnet Motor Technology

-

Unlocking the Future: How Imperial Electric Permanent Magnet Motors Enhance Energy Efficiency

-

Why Choose Permanent Magnet Stepper Motors for Your Next Project?

-

Top 10 Benefits of Using a 90V Permanent Magnet DC Motor for Your Projects